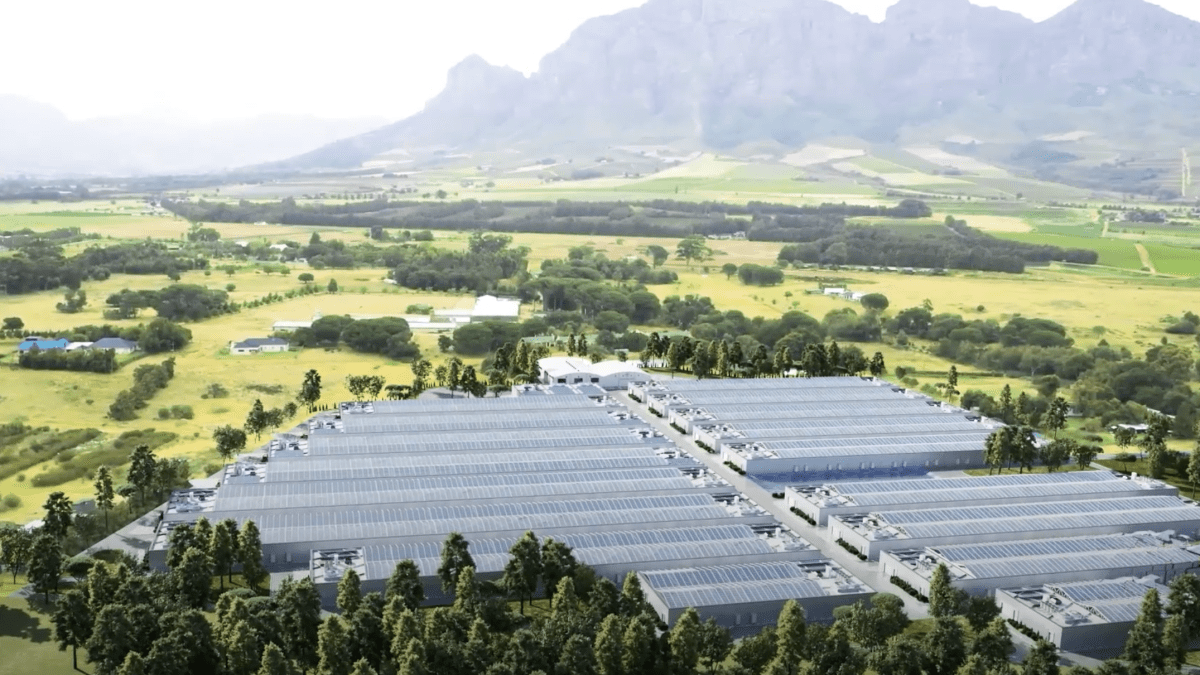

Brand new! The development of the plantation in South Africa and its unique advantages!

LIVE tour of the current 20 hectare Giga-Farm in Paarl, South Africa

19. October 2022Welcome to the first episode of iPlantTV. With this format we would like to give more insights and

impressions into our work and at the same time show the progress of plantations and more.

Starting with the construction of the cannabis farm in South Africa, we would like to explain to you

the steps of how such a plantation is built and in which phases we are currently.

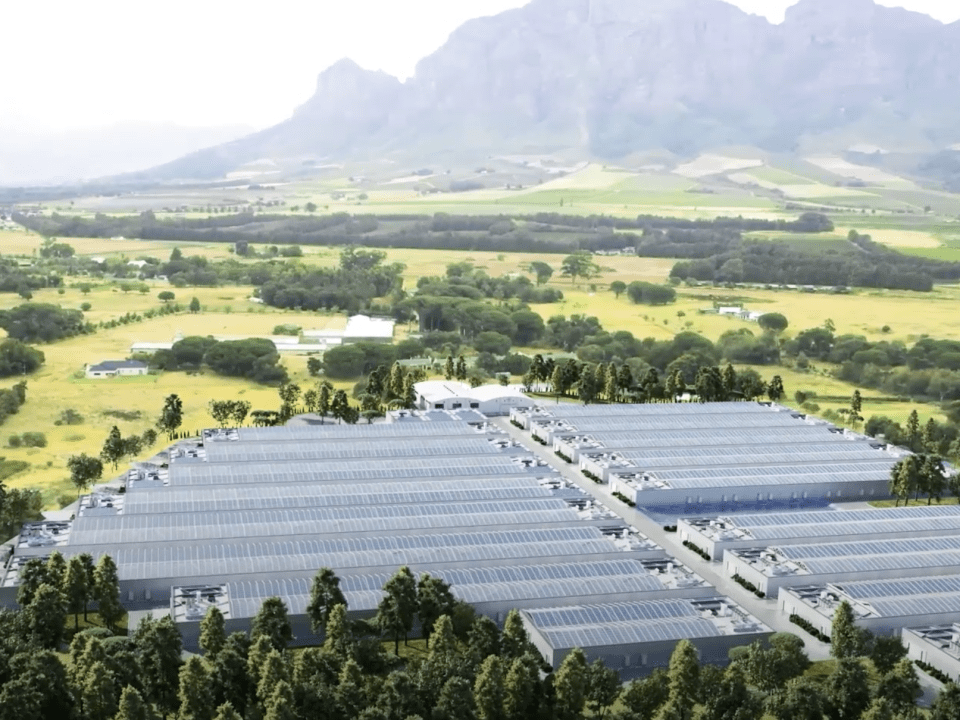

It is important for you to understand that we cannot publish exact construction plans for security

reasons, as this would mean a big risk for the project. Nevertheless, we have provided you with a

precise illustration which will help you to better understand the construction.

The whole project covers a radius of about 20 hectares of land, which is about 28 football fields in

comparison - a huge project! We are currently building phase 1 and phase 2 on a part of the area.

You will receive the exact time schedules as well as further information on the grow there

internally as a customer or partner.

The so-called "post-harvest" process, i.e. the drying, pruning, packaging, etc. takes place under

EU-GMP certified guidelines, which, simply explained, fulfils a certification for certain medical and

hygienic requirements. This means that high quality goods are produced and made ready for

export under the strictest standards.

This works through a very specific system that we use. First of all, we use a closed "Cultivation

block", i.e. a closed cultivation area, by means of which it is possible to comply with the

necessary standards, while at the same time making the valuable sunlight available to the plants.

The whole thing happens in a "greenhouse", in which case there is the possibility to absorb

sunlight from above and still keep the lower area closed. The great advantage of growing in South

Africa is, among other things, that there are long sunny days and the plants can grow under partly

natural conditions. This not only improves performance, but also saves energy consumption by

using less LED lighting. Here, we only "supplement" with LEDs to create a balanced climate

across the entire area. We will use a modern technical system that ensures that each plant gets

exactly the right amount of light. This is important to ensure that the flowers all have the same

cannabiniod spectrum.

In these "Cultivation Blocks" a plant grows for about 70-90 days. This varies depending on the

variety, growing strategy and flowering time. At the end of the day, the given team of experts

determines the strategy and ensures that the same conditions, i.e. room temperature, humidity,

nutrient & water supply etc. are identical in each block. In this way, a balanced harvest can be

achieved, which is precisely tuned to produce a maximum number of grams with the best

possible quality

However, harvesting is a very complex process and not something that can be done in a few

hours. After the actual harvest, the drying phase begins. After that, the flowers are gently

separated from the rest of the plant. There are certain internal processes for this procedure, which

are not publicly disclosed. What is nevertheless transparently shown in the processing is that

parts of the harvest can also be processed into oils or other products directly on our premises.

Depending on the customer order, this is an individual process. In addition, as many components

of the plants as possible will be further processed in the future, so that maximum use is made of

them.

In the last process, the legal basis for proper export is thus created. This is not standard logistics,

as this process is subject to the highest professionalism and is very demanding. This means that

a separate legal department now handles the freight and coordinates the official requirements

with the buyer before the goods are finally shipped.

Furthermore, the set-up for securing the operation is very exciting. In addition to gigantic water

tanks, there is also a so-called control room from which all relevant key figures are systematically

monitored and adjusted around the clock. This serves to ensure that, for example, in the event of

a water shortage, the water tanks can be used, or in the event of a failure of certain lamps, a

generator can step in and replace the energy, so that in no phase of cultivation is the harvest

endangered or the plants lack certain conditions.

Here you can find the iPlantTV explanatory video on this topic. We are looking forward to the next episodes with you.